Solutions

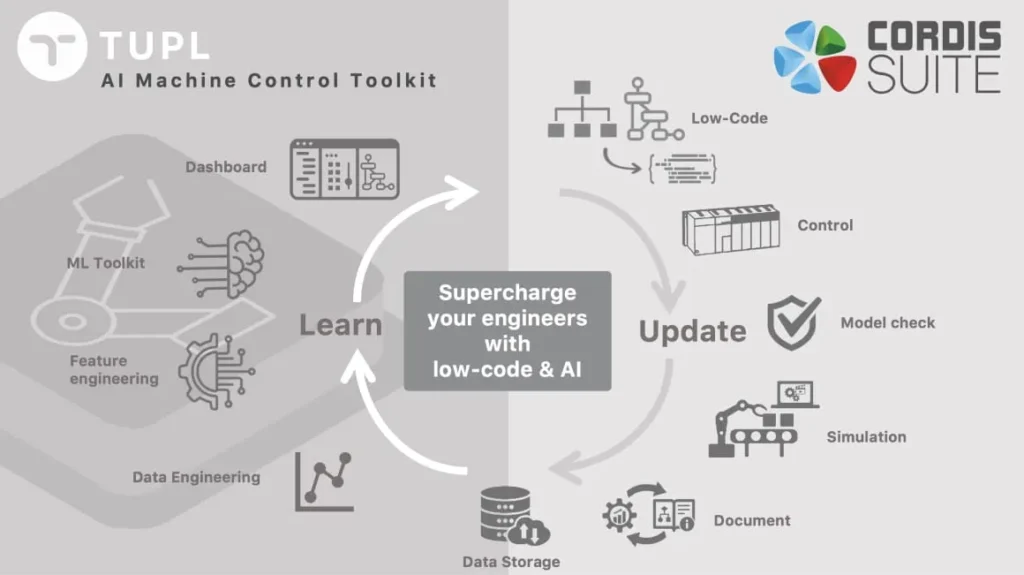

AI Machine Control Toolkit

Providing control and efficiency to your

new industrial machines.

Be faster than ever.

Are you adapting quickly enough through data-driven actions?

The amount of data coming from production lines is huge. The average factory generates 1TB of production data daily, but only 1% of it is analyzed and acted upon using operational data in real-time.

Is your machine control software a Black Box?

- Finding the root cause of an issue is extremely difficult.

- Anomaly detection based only on sensor data can be challenging.

Does it take too long to bring ideas to life in your industrial operations?

- Traditional coding has unpredictable lead times.

- Changing software is complex due to handwritten legacy code.

- Machine Control Developers are a scarce resource.

AI Machine Control Toolkit puts your data to work and shortens innovation cycles

What benefits can you expect from AI Machine Control Toolkit?

3 to 10x

Factories' digital transformation

Improve the ability to adapt and optimize your automation solution

Watch our 2-part video series to see Tupl AI Machine Control Toolkit integrated with Cordis SUITE, specially built to create or refurbish machine control software.

Cordis SUITE - Low-Code Machine Control Platform

- Design Level Thinking: low-code is a visual approach towards software development. With it, software & mechatronics engineers can seamlessly work together.

- Code generation: the low-code models are automatically translated, bug-free, into executable software that works on hardware platforms from multiple vendors.

- Commissioning: it enables engineers to control and visualize machine control data graphically, including all operational and sensor data.

- Data platform: an extremely rich data set is generated automatically so that data scientists can improve OEE.

TuplOS - AI Machine Control Toolkit

- Data Engineering: UI-based data management and transformation; KPI formulas with a low-code approach.

- Feature Engineering: UI-based feature formula generation, with types: Range, Time and SQL features.

- ML Toolkit: creation of machine learning models in which the different ML algorithms are selected by clicking on available options; the training and usage of the model is done within the platform.

- Dashboarding: more than 100 widgets and highly customizable views to analyze data trends.

Get a demo of AI Machine Control Toolkit today

Get started and request a demo to learn how AI Machine Control Toolkit can help you.

Frequently Asked Questions

Below you will find answers to the most common questions about AI Machine Control Toolkit.

How does Tupl AI Machine Control Toolkit work?

The AI Machine Control Toolkit allows the creation of prediction models that keep track of every issue detected in the different machine parts. This data is then used for model performance analysis and retraining.

Using the centralized dashboard allows an overview of the company’s metrics and performance, which results in accurate and early detection of production rate deviations, thus saving time and money.

How does Tupl SaaS work?

AI Machine Control Toolkit SaaS is delivered in cloud service (e.g. AWS, Azure, etc.) and can also be deployed on-premises, in your private cloud, or data center.

Get started with a functional solution in operation within 2-3 weeks. Monthly subscription. No strings attached. Stop at any time.

Are the machine learning models easily trained?

With the use of the Synthetic Data Generator (SDG), one of the components inside the Machine Learning Toolkit, it is possible to train your model before production, in order to detect your production data flaws in advance. So, when the model is deployed, only minimal adjustments are needed for it to function properly.

Cloud VS On-Premise?

Do I need an AI expert or developer on staff?

No-code solutions for AI application development help manufacturers take advantage of this emerging technology without the need to hire technical specialists or investing significant time and capital.

Tupl’s software has a simple and intuitive user interface that enables existing personnel to build AI Machine applications for quality assurance in very little time with relatively small datasets and with no programming required.