Solutions

AI Computer Vision

Solution for Smart

Agriculture

Revolutionizing the agrifood industry through

advanced automation and real-time image analysis

for Pre-Harvest and Post-Harvest.

Are you still relying on manual processes to manage your field operations?

Automation optimizes harvesting as new computer vision technologies allow for counting, sorting and quantifying fruit with unprecedented accuracy, helping to optimize the entire harvesting process.

How are you assessing if your crop is ready for harvesting?

- Low accuracy.

- Manual processes.

Are you optimizing your quality control processes with AI Computer Vision?

- Low consistency.

- Poor quality control.

- Difficult to create new models or combine with others.

Tupl AI Computer Vision Solution

What benefits can you

expect from the

AI Computer Vision Solution

for Smart Agriculture?

Discover how our solution can transform your agricultural business, offering control, flexibility and optimal management of your resources, from the field to the final consumer.

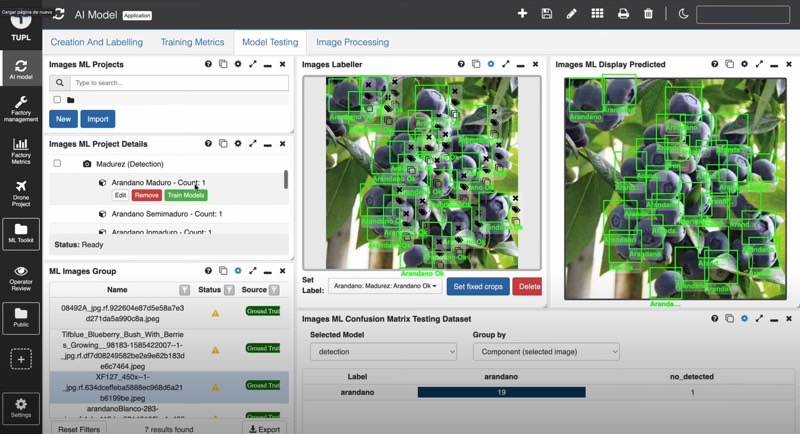

Pre-harvest

- Analyzes images and videos to assess fruit ripeness by detecting color, measuring size and quantifying production volume.

- Allows counting, sorting and quantifying fruit with unprecedented accuracy.

- Facilitates planning and decision making, ensuring that harvesting takes place at the optimal time.

Post-harvest

- Ensures quality control of production lines.

- Automates quality inspection with 100% detection accuracy.

- Reduces costs and improves the quality of the final product.

Technology advantages

- Compatible with any type of vision hardware

- Ability to retrain existing models and create new custom models to suit specific use cases.

- Control your own data: the no-code approach provides the independence to create and adjust vision models without the need for programming knowledge

Get a demo of the AI Computer Vision Solution for Smart Agriculture

Get started and request a demo to learn how the AI Computer Vision Solution can help you.

Frequently Asked Questions

Below you will find answers to the most common questions about AI Computer Vision Solution for Smart Agriculture.

How does the AI Computer Vision Solution for Smart Agriculture work?

How does Tupl SaaS work?

AI Computer Vision Solution for Smart Agriculture SaaS is delivered in cloud service (e.g. AWS, Azure, etc.) and can also be deployed on-premises, in your private cloud, or data center.

Get started with a functional solution in operation within 2-3 weeks. Monthly subscription. No strings attached. Stop at any time.

What are the applications of computer vision in agriculture?

How accurate are the ML models?

Are the machine learning models for computer vision in agriculture self-trained?

Manual vs Automated Visual Inspection?

Cloud VS On-Premise?

How much data / how many images do I need to get started with the AI Computer Vision Solution for Smart Agriculture?

Do I need an AI expert or developer on staff?

No-code solutions for AI application development help manufacturers take advantage of this emerging technology without the need to hire technical specialists or investing significant time and capital.

Tupl’s software has a simple and intuitive user interface that enables existing personnel to build Vision AI applications for quality assurance in very little time with relatively small datasets and with no programming required.